WOOD PANEL MANUFACTURING

The production process is divided into separate phases, with each employee specializing in a certain task. The phases of production are:

- Material processing

- Assembly of panel frame and sheet materials

- Laying of thermal insulation and vapour barrier, furring assembly

- Assembly of doors and windows

- Wall panel preparation for transport

In accordance with project requirements, wall panels are processed in several stages to ensure the required level of readiness. Throughout the production process quality conformity checks are carried out to maintain the quality of the end-product.

The manufacturing process begins with selecting the needed materials and cutting them to the required specifications. Then the materials pass on to the frame panel assembly surface, where all the elements are conjoined with nails or screws, and after a geometry test the required sheet material is fixed to the panel. In the next phase of production the wall is flipped onto the other side, thermal and vapour insulation is laid and the furring fixed. In the following phase the door or window is put in, and the panel is completed. After a final quality check, the product is packaged and shipped to the client.

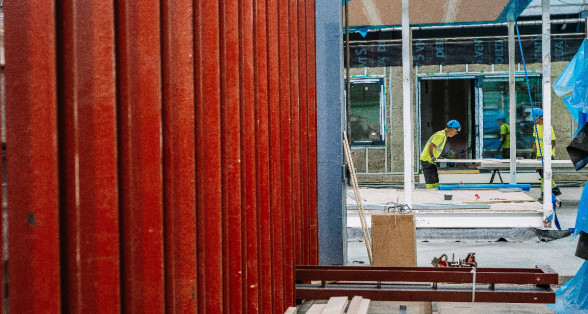

MODULE ASSEMBLY

On production surfaces, in accordance with blueprints, the load-bearing elements of the panels are assembled, any engineering networks are installed, thermal insulation is put in and the panel receives an outer plating with sheet material. When the panel is completed to the set-out specifications, it is moved to the module assembly zone. Module assembly begins with the floor covering panel and moves upward. That is, the floor panel is fixed to the columns, then the wall panels get assembled, followed by conjoining the roof panel with the columns and wall panels. The module assembly process includes waterproofing of panel seams, to adhere to air non-permeability requirements and ensure higher energy efficiency.

The modular frame assembly process differs from traditional frame assembly, in that the load-bearing frame is assembled in parallel with the partially constructed side elements, and part of the load-bearing frame is built into the panels during manufacture. Utilizing this approach reduces the chance of altering or damaging the geometry of a construction, as the module’s geometry is directly tied to the precise measurements of the elements to be assembled and the thresholds in load-bearing element seams.